BA30 Front Wheel

The BA30 is a quality alloy rim designed to withstand a real beating.

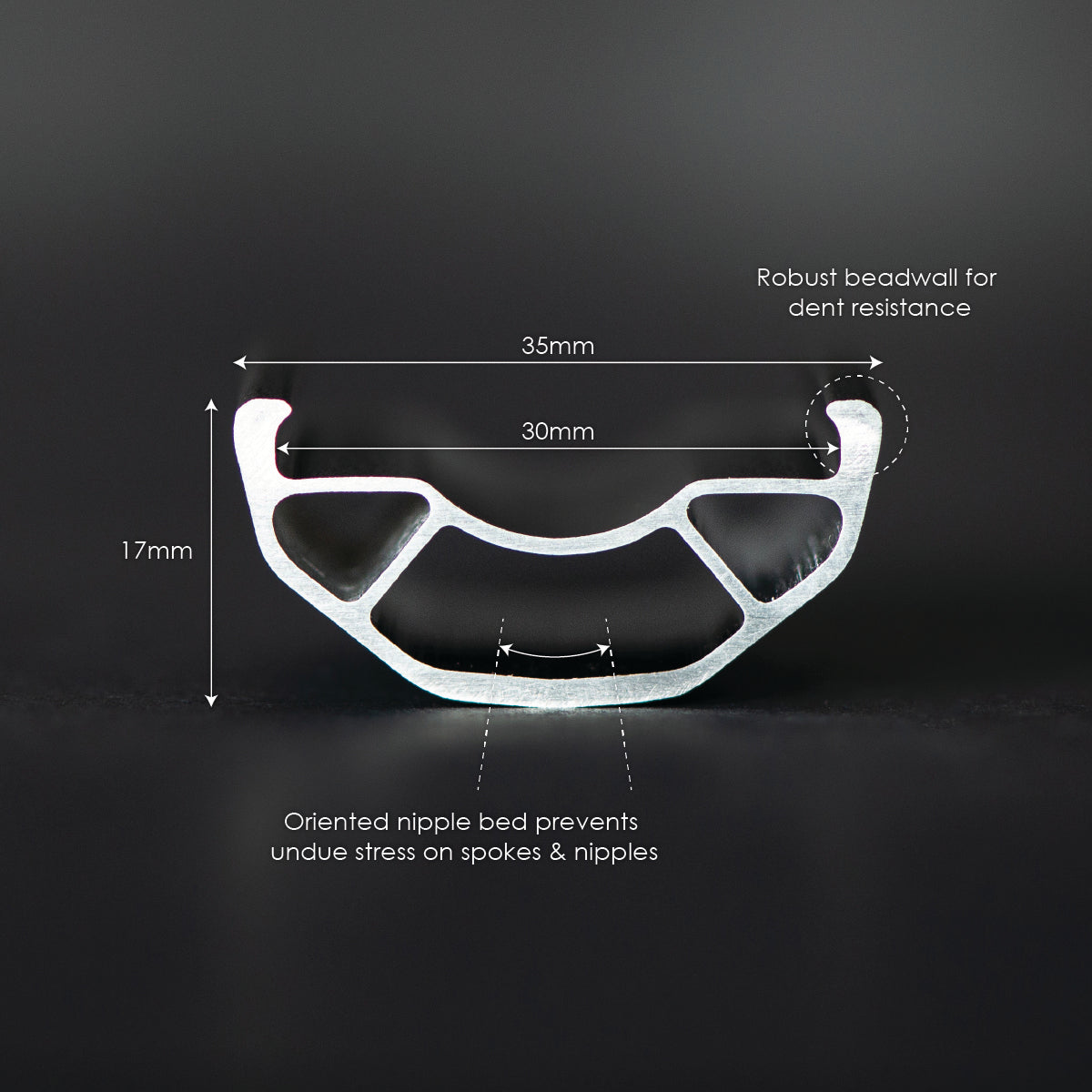

This is the rim for high-impact riding when the trails are rough and rugged. With an internal bracing structure, the BA30 has torsional stiffness for directional control in demanding circumstances. The BA30 features a thick bead wall adjacent the tire to resist impact deformation, with a wider, rounded top-edge to reduce sidewall cuts. The nipple/spoke bed is oriented to the spoke direction to reduce weakness caused by bend in the spoke at the nipple hole. The BA30 is made with premium alloy, extruded with an internal brace profile and carefully formed for consistent shape. It is then fusion welded and ground for a strong precise finish. Our fusion welding system leaves a perfect seamless joint that becomes the strongest section of the rim ensuring that your rim won’t split if you impact at the seam.

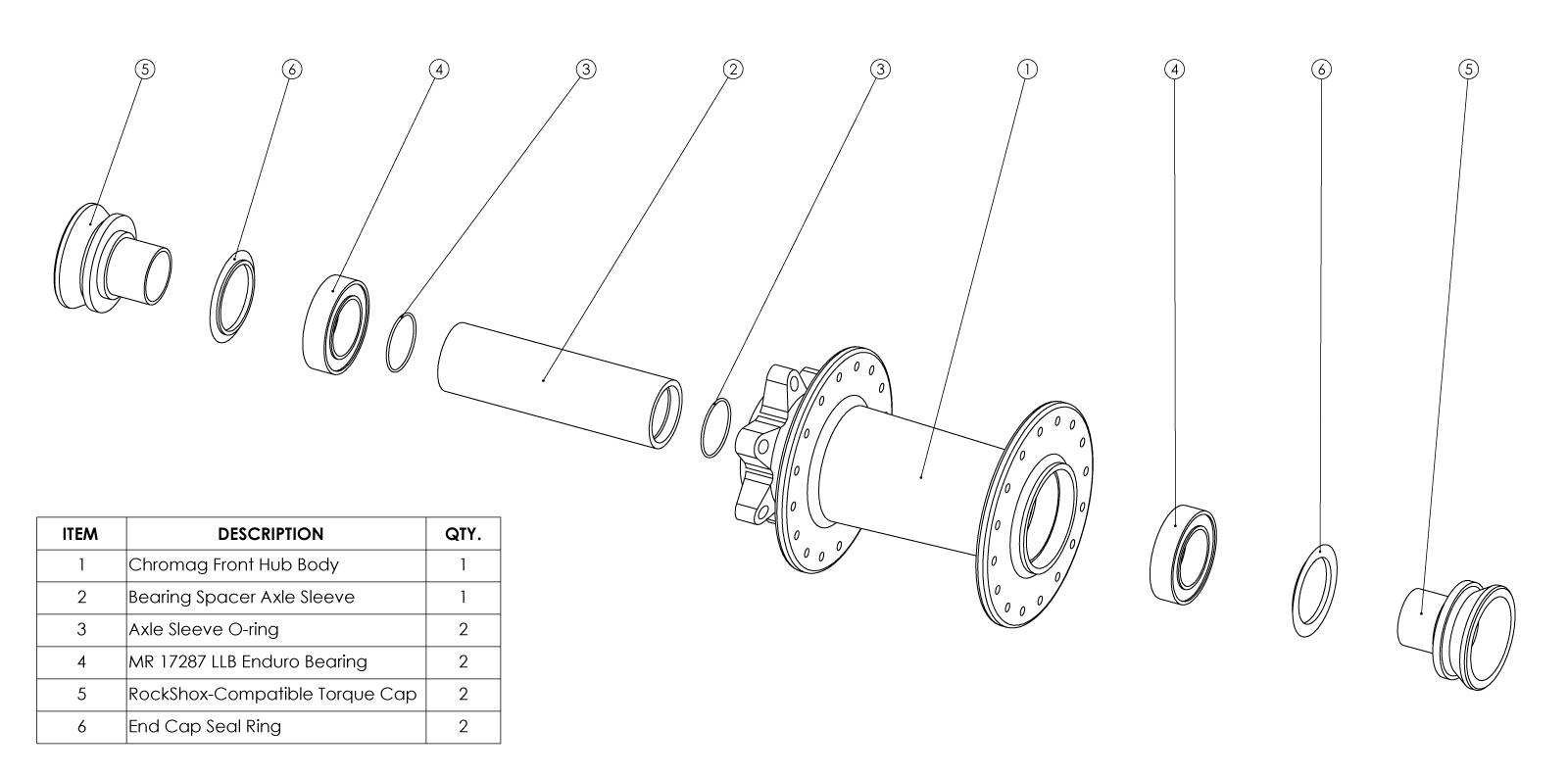

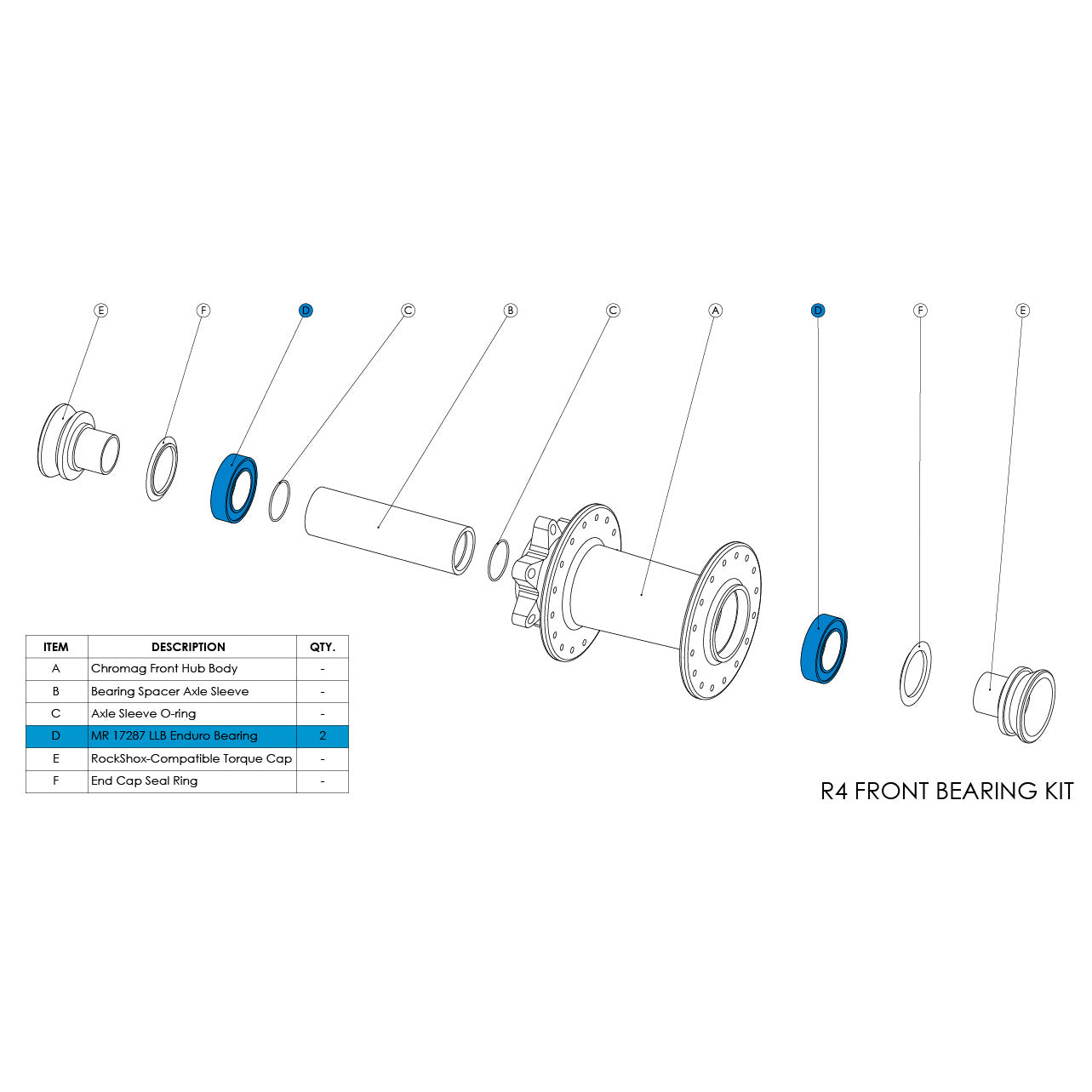

The rims are laced to our new R4 hub. The R4 is designed to be a solid, reliable hub with a durable axle assembly and robust set of bearings.

Use code: WheelieGood to receive $50 off when you buy a front and rear wheel.

Hub Specs

Axle Diameter // 15mm

Spacing // Boost 110mm

End Caps // Regular or RockShox Torque

Tubeless // Tubeless Ready, Taped, Valves Included

Spokes // 32

Disc Mount // 6 Bolt

key features

Design Considerations

Wheel FAQ's

Our wheels are pre-stressed and ready to ride out of the box. We also use Nylock spokes to keep the tension where it should be. We've found this to last longer and stay in place better when adjustments are made later on.

However, like all wheels there is a bedding-in period, so be sure to keep an eye on spoke tension after the first few rides.

Torque caps are a RockShox product that allow for greater stiffness between the front hub and fork interface. Newer RockShox forks will work with or without them.

All other fork brands will not work with Torque Caps.

Wheels come pre-taped with tubeless valves installed.

All you need to do is install tires and sealant.

If you got our wheels on a complete bike from us, tires and sealant will already be installed and seated, just inflate to desired pressure.

Provided the rim does not have a crack, you can use an adjustable wrench to gently bend it back to help your tyres seat properly. (One of the benefits of alloy over carbon)

Use a rag or an old inner tube to prevent scratching your rim, and be careful to avoid puncturing your rim tape!

You'll likely need to adjust spoke tension if your wheel has taken a hit hard enough to dent it.

If you notice any play in your wheel when your axle is tight its time to check things out. Similarly if you can hear or feel the bearings grumble when spinning, an investigation and likely fresh set of bearings would be a good move.

If you are doing a pre-season refresh or just giving your bike a thorough going over then cleaning and re greasing your freehub body is a good move, removing any contaminants and adding fresh clean grease is a good way to reduce long term wear.

They both use our top end alloy with a fusion welded seam-ground join, and have a 30mm inner width.The main difference is the BA30 has some extra internal bracing, making it stronger and a bit heavier.If you're really on the fence, run a Phase on the front and BA on the rear.

The Phase and BA are fusion welded, and post ground which makes the join the strongest part of the rim!The Ally is pinned at the joint, which is more simple and less labour intensive, but not as strong. The Ally is also slightly heavier as the alloy used has slightly less strength than that of the BA and Phase.